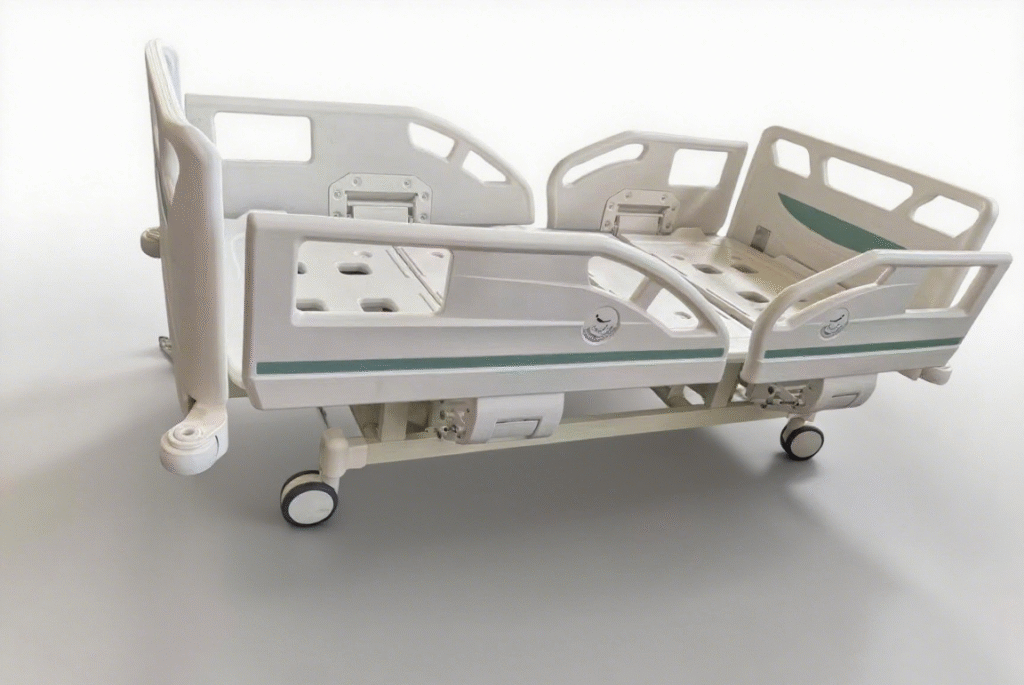

At the end of the white corridor of the hospital, each bed is a silent island, carrying the weight and hope of life. As the core carrier of medical space, modern medical-grade beds have long surpassed traditional cognition and become a medical solution that integrates ergonomics, intelligent technology, and humanistic care.

1.Technology empowers and redefines comfort and safety

Our medical-grade beds use aviation-grade aluminum alloy frames, which ensure load-bearing performance while achieving lightweight design. The bed can be raised and lowered from 30 to 70 cm to meet the operating height of medical staff and the needs of patients to stand up independently. The five-section electric bed board is driven by an independent motor and can be accurately adjusted to 12 clinical positions, such as sitting, semi-recumbent, and reverse Trendelenburg positions, effectively preventing pressure sores and reducing the burden on the heart and lungs.

The intelligent sensing system is called an “invisible guardian”: the pressure sensor monitors the patient’s body pressure distribution in real time and automatically adjusts the support strength of the mattress; the bed leaving alarm function triggers an audible and visual prompt within 0.5 seconds when the patient accidentally gets out of bed, and simultaneously sends an alarm to the nurse station. These technical details make every turn and every treatment action safer and more efficient.

2. Patient-centered humanized design

The opening and closing design of the bed guardrails is ingenious: the double-sided one-touch lifting guardrails can rotate 90° in 1 second, which not only ensures safety but also facilitates family care; the bedside integrated control panel uses a luminous touch screen, so patients can easily adjust the bed angle at night. Detailed designs such as foldable infusion stands, magnetic bedside cards, and hidden storage drawers increase the space utilization rate of the ward by 40%, making the space both functional and comfortable.

3. Quality commitment throughout the entire life cycle

From raw material procurement to finished product delivery, each hospital bed must go through 18 strict quality inspection processes. We have established an industry-leading fatigue test laboratory to simulate 200,000 bed lifting and 100,000 guardrail opening and closing to ensure 10 years of trouble-free operation of key components. The matching bedding uses nano-silver ion antibacterial fabrics, which have been certified by a third-party testing agency to have an antibacterial rate of more than 99% against Escherichia coli and Staphylococcus aureus.

In the journey of life, hospital beds are an indispensable station. We always believe that every precise angle adjustment and every thoughtful detail design create a better recovery environment for patients. Choosing our medical-grade beds means choosing to protect life with technology and convey warmth with craftsmanship. For more product information or customized solutions, please feel free to contact our professional team